Products

Our damper valves

ARP damper valves are specifically designed for low pressure and medium to high temperature flue gas up to 1000°C.

We manufacture a wide range of dampers suitable for various industrial appplications such as incineration, biomass combustion plants, thermal power stations, foundries, industrial furnaces, dryers, gas turbines, air treatment plants and many other thermal processes.

Selecting the right damper valve is important to optimize the operating industrial process.

Our dampers valves are suitable for both control (regulating, modulating) or on/off service (isolation, interception).

Available drive configurations selected to suit the application and customer requirement:

- lever or handwheel;

- pneumatic actuator, positioner and solenoid valve;

- electric actuators.

Actuators are sized to function reliably over the full range of temperature and pressure with a safety factor. Drives are fitted at the factory and fully tested prior to shipment.

Every damper is carefully arranged and tested to standards and customer specifications by our qualified technicians. All valves can be equipped with microswitches for position monitoring.

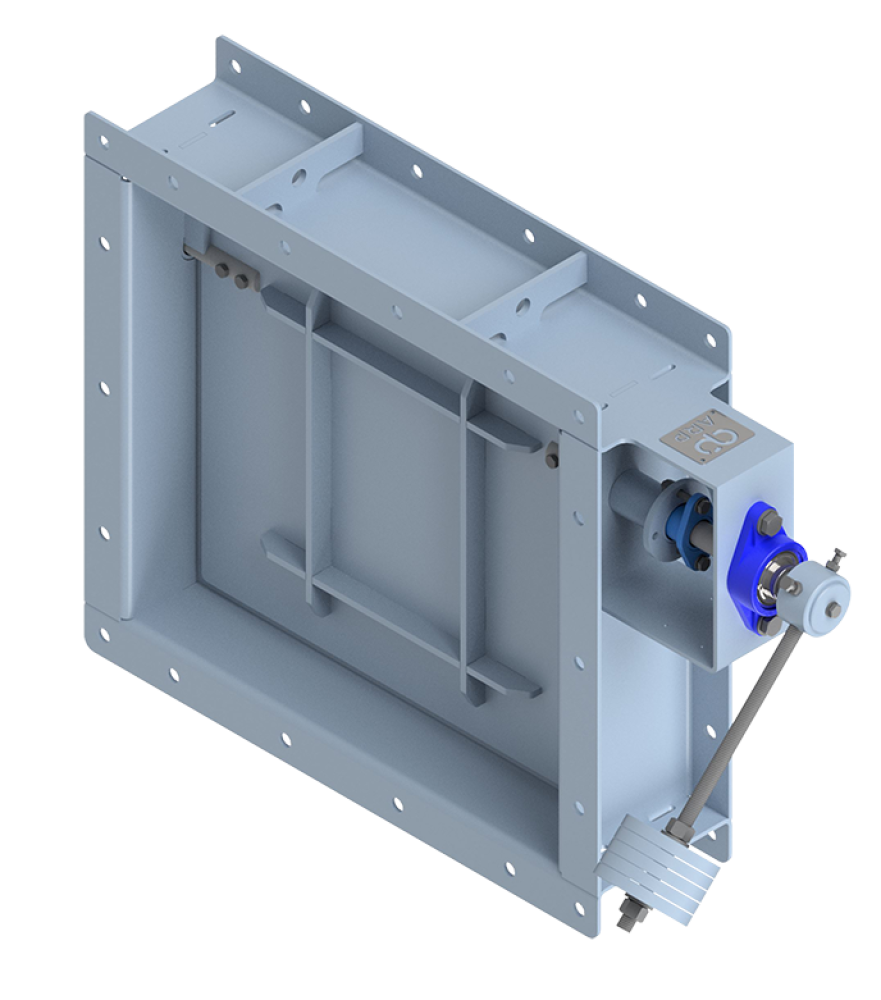

The carpentry construction allows the choice of any type of material depending on the use, temperature and corrosive media. Damper dimensions, cross section and connections can be customized to meet any process requirement.

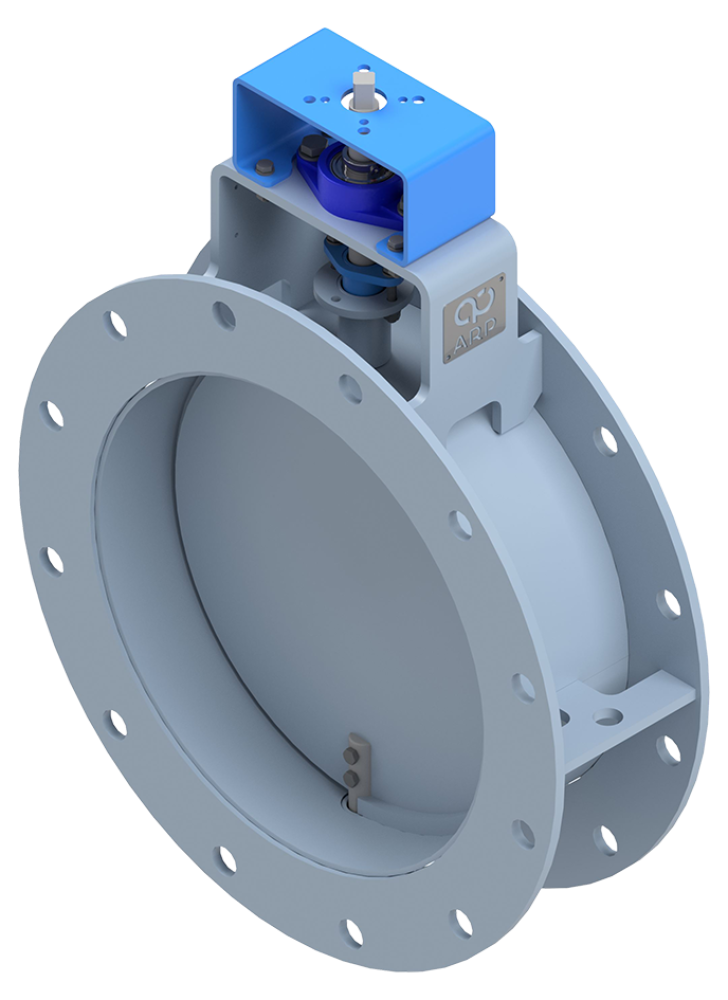

In butterfly valve applications, the disc rests securely on the seat to close and seal the valve.

Seats are designed to keep the seal intact despite the thermal, friction, and impact stresses of a process.

Our dampers are available with several seat configurations:

- No seat between the blade and frame: used when no specific seal is required – 95% Geometric sealing of total internal section.

- Metallic blade seat: used when a minimum tightness is required – Achievable tightness Class I to II, according to FCI 70-2.

- Blade seat in harmonic steel: used when a metal seat is required to improve tightness – Achievable tightness Class I to III, according to FCI 70-2.

- Soft seat: used when good tightness is required – Achievable tightness Class II to III/IV, according to FCI 70-2.

- Air sealing with harmonic metal seat: used when excellent sealing is required – total sealing with pressurized sealing chamber.

No seat – Geometric tightness 95% .

Metal to metal – FCI 70-2 max tightness class II Harmonic steel lamellas – FCI 70-2 max tightness class III.

Soft seat – FCI 70-2 max tightness class III/IV Air sealing – Perfect tightness with pressurized air chamber.

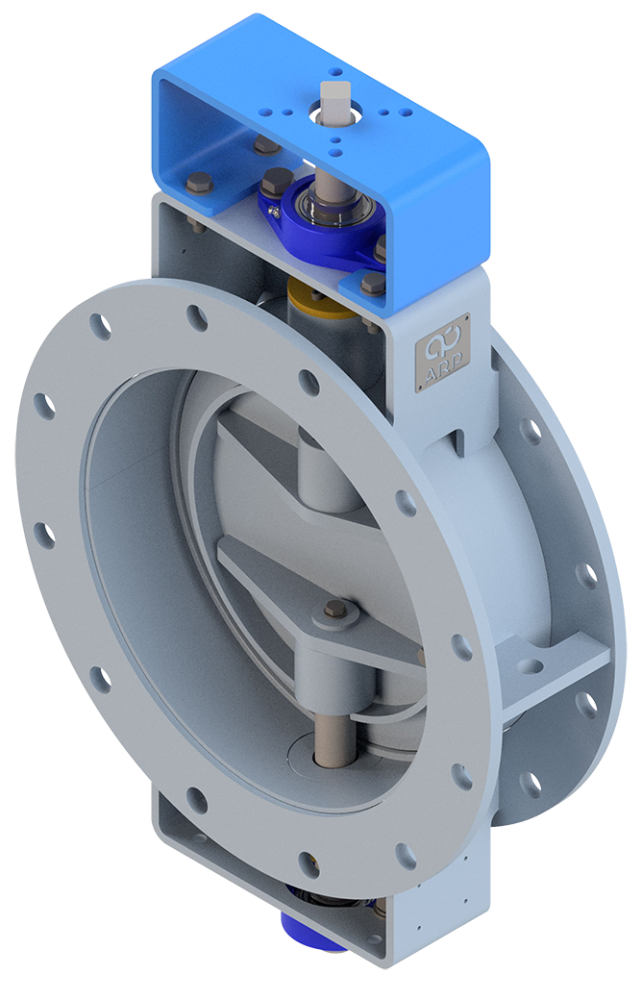

As standard the shaft sealing is guaranteed by braid packing. In case of perfect tightness requirements , the integrated lantern ring with compressed air insufflation option is available.

Lantern ring is considered a crucial element as packing tends to generate heat. Heat increases wear which can shorten the life of the packing and the shaft. Placing a lantern ring between packing rings extends the life of the packing, the stuffing box, and the shaft. Ultimately, this increases the lifespan of the whole damper long term.

Other types of shaft sealing are available on request.

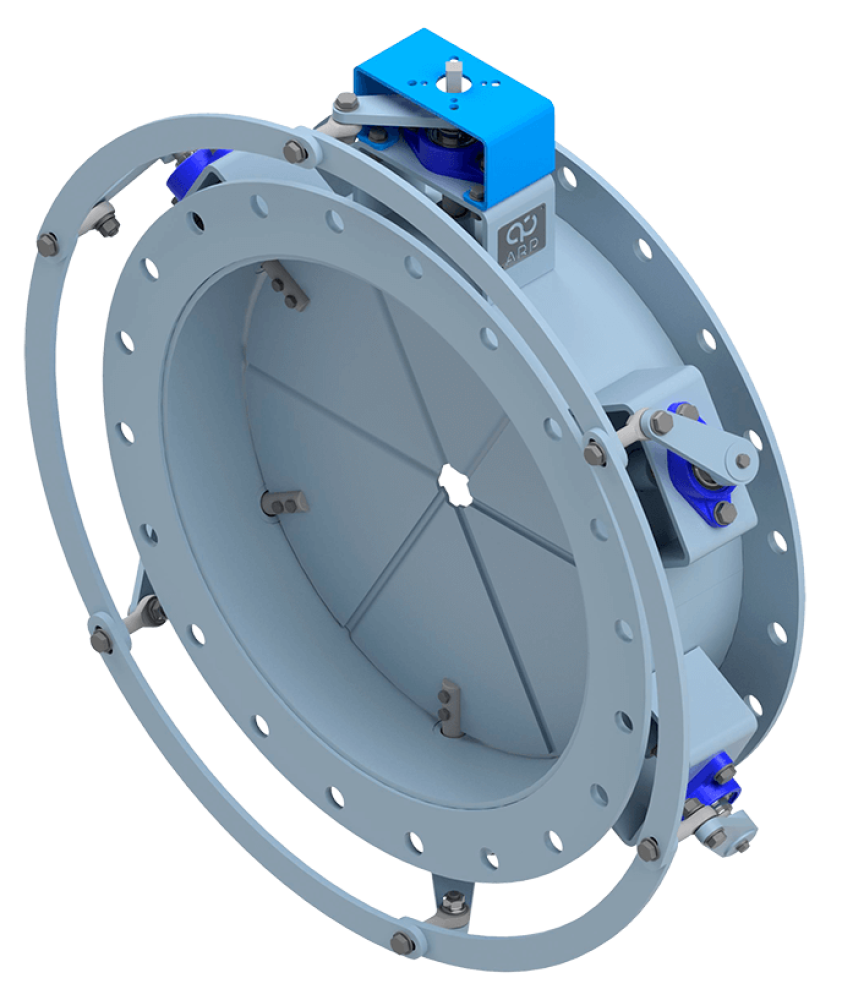

BUTTERFLY DAMPER

All butterfly valve series are characterized by a circular cross section with concentric single or double blade.

DOUBLE OFFSET VALVE

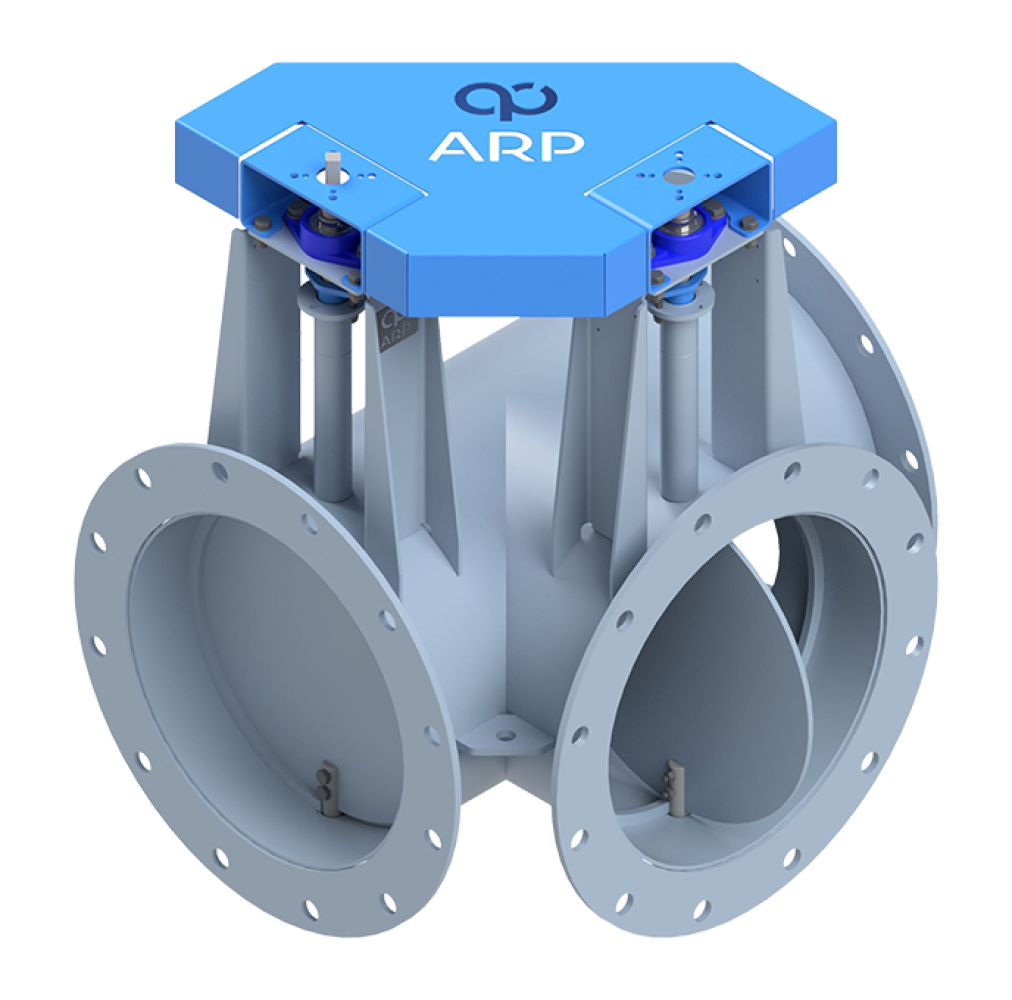

BY-PASS DAMPER

The by-pass damper is a three way valve that allows the engine exhaust flow to be diverted towards the bypass chimney or towards the boiler; intermediate positions can be used for partialization or preheating.

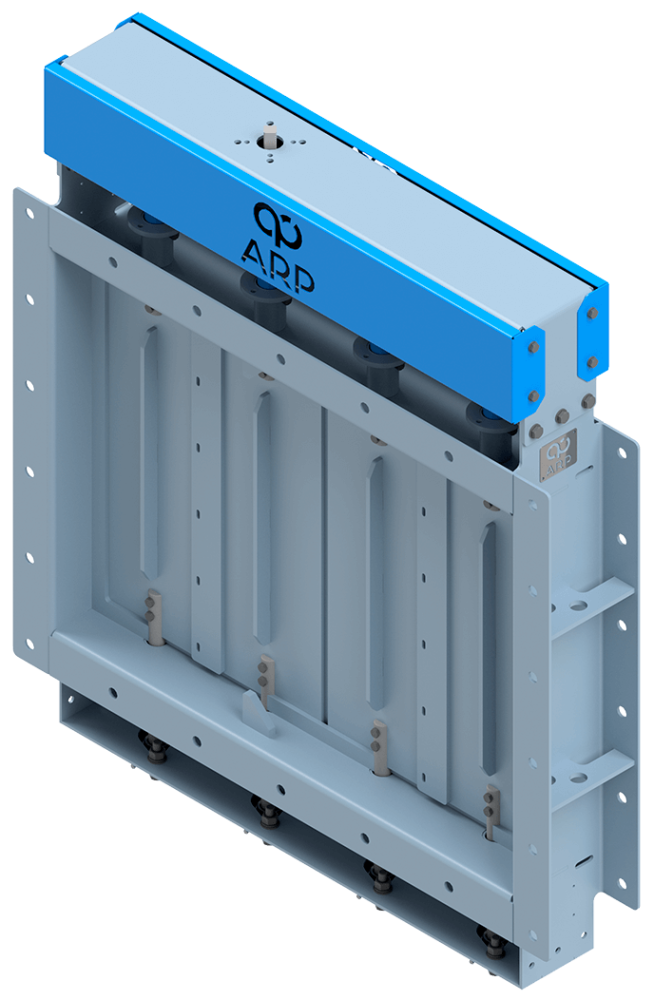

LOUVER DAMPER

RADIAL VANE DAMPER

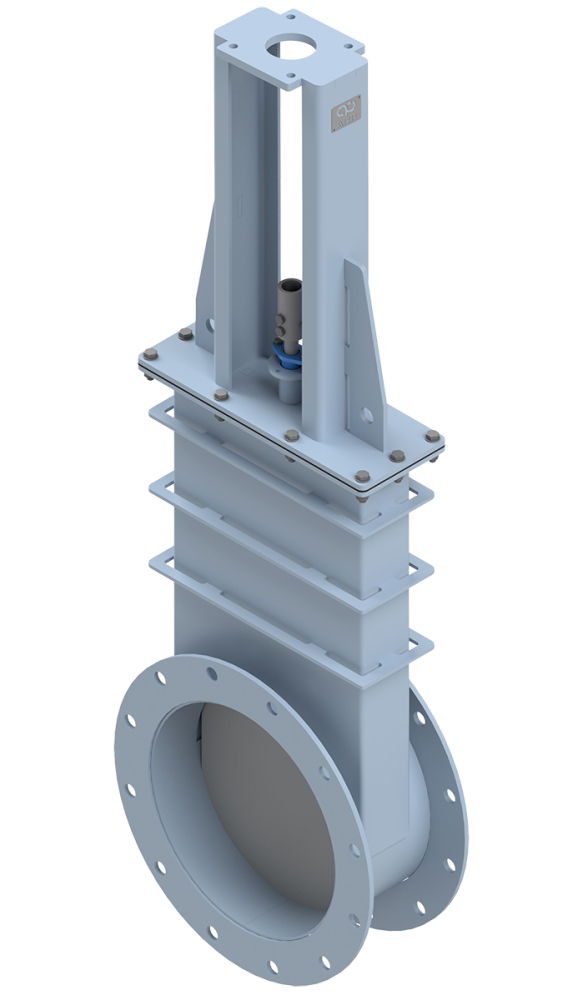

GUILLOTINE DAMPER